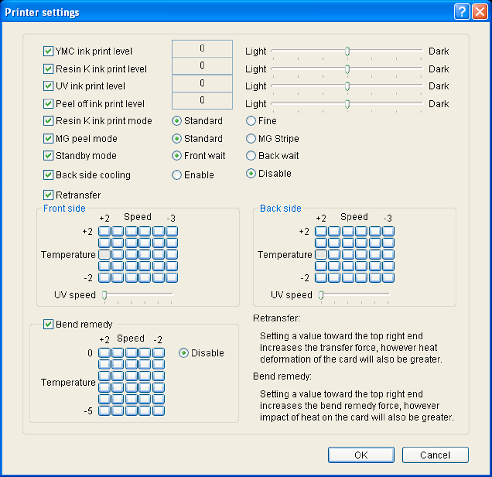

[Printer settings] Dialog Box

Settings related to the printer.

Select the checkbox for the setting item to enable, followed by specifying a value. Doing so prints the data using the set values.

When the setting is not enabled, data is printed using the preset values of the printer unit.

Select the checkbox for the setting item to enable, followed by specifying a value. Doing so prints the data using the set values.

When the setting is not enabled, data is printed using the preset values of the printer unit.

YMC ink print level

Print density of the YMC ink.

Use the [+] values to increase, and [-] values to decrease the density.

Use the [+] values to increase, and [-] values to decrease the density.

Resin K ink print level

Print density of the Resin K ink.

Use the [+] values to increase, and [-] values to decrease the density.

Use the [+] values to increase, and [-] values to decrease the density.

UV ink print level

Print density of the UV ink.

Use the [+] values to increase, and [-] values to decrease the density.

Use the [+] values to increase, and [-] values to decrease the density.

Peel off ink print level

Print density of the peel-off ink.

Use the [+] values to increase, and [-] values to decrease the density.

Use the [+] values to increase, and [-] values to decrease the density.

Resin K ink print mode

Print quality of the Resin K ink.

Selecting [Fine] enhances the printing quality, but slows down the printing speed.

Selecting [Fine] enhances the printing quality, but slows down the printing speed.

MG peel mode

When a magnetic encoder unit is installed, selecting [MG Stripe] optimizes the peeling operation of retransfer films for magnetic stripe cards.

Standby mode

Specify a position when a laminator is connected.

This is used for setting the standby position of the card during double-sided printing until the laminator is ready. [Front wait] is selected by default.

This is used for setting the standby position of the card during double-sided printing until the laminator is ready. [Front wait] is selected by default.

Back side cooling

This setting is only valid during double-sided printing.

Setting this item may help to reduce card bend during double-sided printing. However, the printing time may also be affected.

Setting this item may help to reduce card bend during double-sided printing. However, the printing time may also be affected.

Retransfer

Settings related to retransfer. Click on the corresponding square to change the value.

Setting a value toward the top right end increases the transfer force. However, the stronger heat also increases the deformation of the card.

- Temperature

Temperature of the retransfer heating roller.

- Speed

Retransfer speed.

- UV speed

Setting for printing the retransfer film in two panels when UV ink is used.

It is used to set the speed of the retransfer heating roller during retransfer of the UV ink.

This setting helps to increase the retransfer speed without affecting the quality of the UV print.

Bend remedy

Settings related to bend remedy.

Click on the corresponding square to change the value.

Click on the corresponding square to change the value.

Setting a value toward the top right end increases the bend remedy force. However, the stronger heat may have a greater impact on the card.

To disable bend remedy, select the [Disable] button.

- Temperature

Temperature of the bend remedy heating roller.

- Speed

Bend remedy speed.

Cautions

The optimal retransfer and bend remedy settings vary according to the card type as well as environment in which the printer is used. Adjust the setting according to the actual environment.

If the retransfer or bend remedy settings are different from the preset temperature of the printer, it may take a while before printing starts.

There is only one standard retransfer temperature. Altering the retransfer temperature on one side changes the temperature on the other side.

Bend remedy is effective when printing on only one side. Setting bend remedy to a high temperature during double-sided printing may cause the card to deform significantly.

As such, select the [Disable] button during double-sided printing.

As such, select the [Disable] button during double-sided printing.

When bend remedy is disabled using the [Disable] button, the speed is automatically set to the maximum value of [+2].

The stronger the bend remedy force, the less glossy the surface of the remedy side will be.

Close